Introduction

Most freight and logistics companies know the importance of understanding the profitability of their products, customers, and operations at a granular level.

There’s good reason for this.

Freight and logistics companies know that size and complexity of their customer base and operations provides ample opportunities for inefficiencies and unprofitability to hide. They know that by using high level models, or none at all, they have limited ability to confidently identify pockets of profitability amongst customers, products, operations, lanes, weight bands, and so on.

They know that unless they have accurately modelled their operations at a granular level, they will be managing by averages. Averaging costs across large groups of customers and areas of the operation guarantees that, at scale, they will not be able to tell good customers from bad, or efficient operations from inefficient ones.

But despite recognising the benefits of a multi-dimensional understanding of profitability, fewer than 20% of companies are using a profit model. Many companies tell us it is difficult to ensure that their profit model is are accurate, that it is difficult to keep it up to date, to know how much to invest in developing it, or how to earn a return on this investment. It’s easy to make mistakes that have disastrous consequences.

Consider the road taken by one national freight and logistics operator. Following five years of growth in revenue and profit, they experienced a sudden drop in both. Management were at a loss to diagnose the underlying cause – was it all due to lingering effects of the global financial crisis? Were their largest customers strangling them with their pricing power? Or was it that their smallest customers who were walking out the door were actually their most profitable? They knew they needed a solid fact base to tell them which of their products, customers, geographies, and operations were profitable. But just at the time that they most needed insights, they received news that their head office was starting a global profit model project. This programme would involve all regions feeding their data into a model specified and controlled by the group Revenue Management Office.

Months elapsed. Time and resources were devoted to developing frameworks aligned to the head office view of the world, but had little relevance to or buy-in from the local company. As the head office programme ticked along, consulting and designing, and results continued to deteriorate, local management knew that they needed to take matters into their own hands before it was too late. They developed their own model in a rapid skunkworks project and began implementing profit improvement initiatives. Once global head office saw the value that they had added to the business, they were given leave to opt-out of the global programme and expand the scope and resources of their successful local model.

This is not an unusual experience. Many companies fail at this process. But for the many that fail, we have also seen phenomenal successes. Companies have used profit models to turn around their businesses, doubling or tripling their EBITDA, and adding multiple percentage points to their Return on Sales.

Our work with hundreds of companies across logistics and other sectors has helped them navigate the road to a granular understanding of profitability, and shown them how to use these insights to significantly increase revenue and yield, reduce costs, and improve productivity. Many of our clients have witnessed the power of the virtuous cycle from a DPM process.

Having directed or supported DPM engagements of all kinds, including turning around those endeavours that have stalled, PCG has identified many of the reasons why some profit model projects deliver significant results and others fail to make an impact. We have codified these learnings into an end-to-end DPM process.

One of the lessons we have observed is that, when the implementation of a DPM has not been successful, it is usually because the company has taken one of two roads. They have leapt into it without consideration and found themselves bogged down in things like the complexities of edge-case allocations, or they have turned it into a large-scale long-term project, failed to make short-term progress, and lost the support of the executive and operating team.

One of our key observations is that the DPM projects that deliver the best results in the shortest amount of time start with a clear understanding of the capabilities of the company and where they want to get to in the near and medium-term future.

For our clients, the first step in a DPM process is to understand what their capabilities and opportunities are today, where they want to go tomorrow, and develop the plan to bridge the two.

In this whitepaper, we share the details of this structured diagnostic process in the hope that more companies will commence their journey having developed a rigorous starting point.

What is a Dimensional Profit Model (DPM)?

DPMs are advanced cost allocation models which aim to connect customer, product, financial, and operational information using data-driven allocations or direct cost tracing. They avoid the averaging of costs based on proxies such as revenue, consignments, or items, and instead use operational modelling or direct cost tracing to allocate work effort involved directly to the items and consignments that consume resources.

The basic purpose of cost allocation models is to connect activities with the costs that they generate. Without accurate costing, there will be cross-subsidisation of costs. Customers who generate the most cost will be subsidised by other customers because of the averaging of costs across all customers. The organisation will be unable to make intelligent decisions about where to grow, where to change, and where to exit.

Diagnosis, DPM

DPMs are complex beasts.

A high quality DPM will draw together customer metadata, detailed financial data, second by second event data from operating equipment, and a range of other inputs to provide a comprehensive dimensional view of the business.

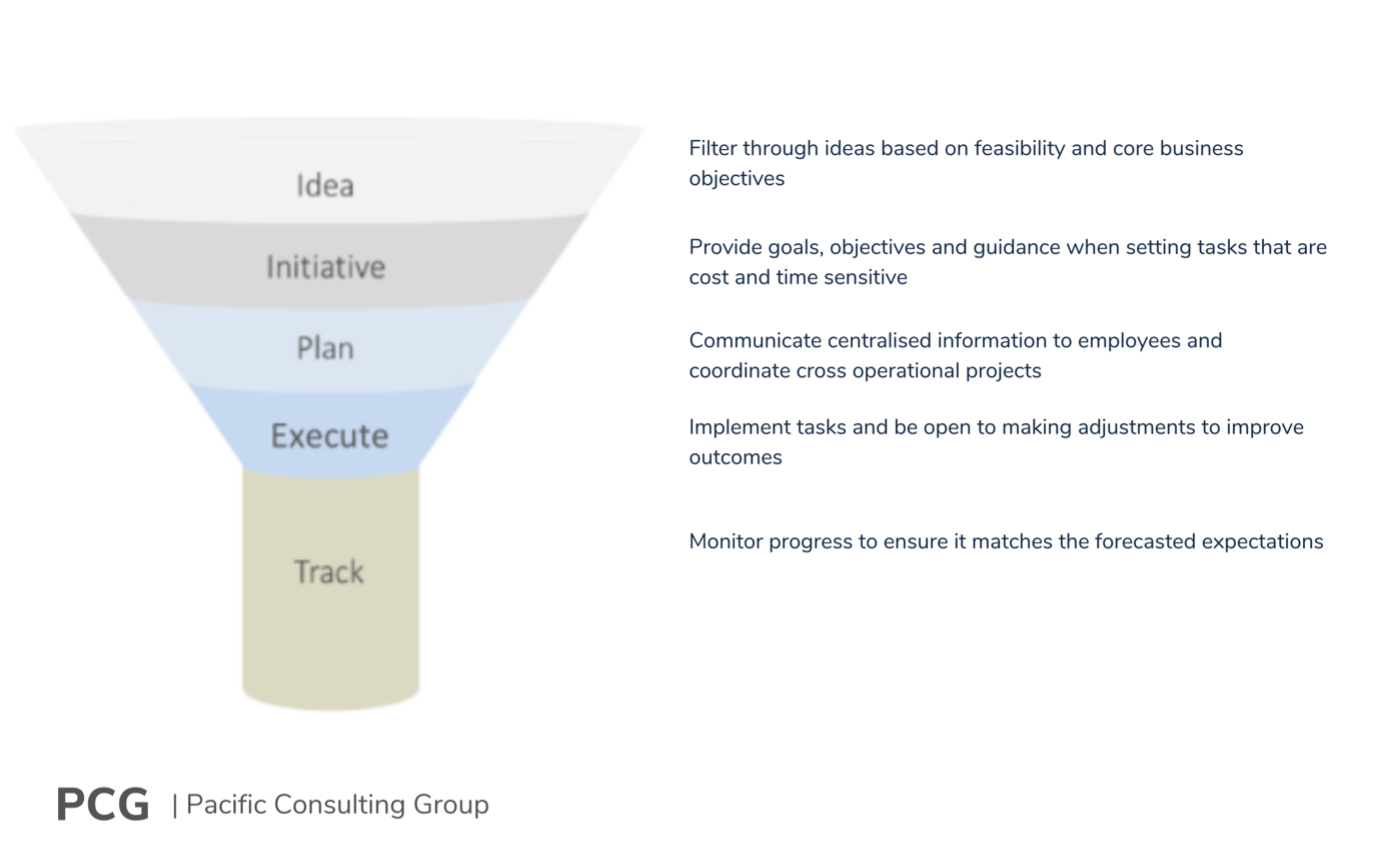

The broad questions that the diagnostic should seek to answer are:

- Where do you want to go?

- What is your current capability?

- What is your investment pipeline?

- Where are the gaps?

- What investments will close the gaps and what is the implementation plan?

For each of these questions we have developed a set of diagnostic tools to support the process.

Step 1: Where do you want to go?

Expert operators can use a high-quality DPM to make improvements across their business, ranging from pricing and yield initiatives to supporting network investment decisions. Some of these uses include:

Pricing & Yield

Case study: A national parcels company updated their pricing for all customers once per year. Their approach was to apply the same change in rates to every customer. With the insights provided by a DPM, the company was able to segment their customers by profitability, and also take into account their history of price changes. These insights allowed them to target customer populations differently; increasing prices for those customers who were unprofitable or misusing the network, and lowering prices for highly attractive customer segments to support retention.

Example uses:

- Dimensional profitability analysis, for example profit by product, customer, lane, item weight band, coincidenceof pickup or delivery.

- Customer segmentation based on profitability, freight profile, network usage.

- Pricing analysis, for example comparing price differences in price per kilogram by customer or product.

Productivity

Case study: Despite an abundance of operational event data generated by processing assets and hand-held scanners, a global freight carrier did not have a rigorous approach to evaluating the performance of their various sites. During the scoping for a new DPM, they were able to leverage the work done to clearly define the performance measures for each site and the data that could support this kind of analysis. Once the model was in prototype, they leveraged the DPM’s view of the event data to create leader boards which allowed them to start improving performance standards for unproductive sites to minimum levels of their peers.

Example uses:

- Productivity analysis for major operating functions like linehaul, processing, and pickup and delivery. For example, supporting daily and weekly reviews of pickup and delivery vehicle fleet productivity.

Sales force effectiveness

Case study: One freight and logistics company was frustrated with the outcomes from incentivising their sales force based on new business revenue. Their top line was growing but so was their cost of freight, because the freight profile of the new business was low quality. Using the output from a DPM, the company could clearly see the link between the low quality of the new business compared to their existing portfolio. They changed selling incentives to include a gross margin measure. This ensured that the sellers were incentivised to win business that didn’t have a negative impact on operational performance.

Example uses:

- Sales force leader boards based on profitability and freight profile quality.

- Tracking changes in profitability across sales territories and customer cohorts.

Network investment

Case study: The product of many years of acquisitive growth, one national logistics operator was facing the challenge of integrating their many networks to improve service and efficiency. In order to make investment and rationalisation decisions, they turned to their DPM to compare productivity across the networks. They were able to highlight asset and sub-network aspects such as high productivity or apparent excess capacity. The integrated nature of the DPM allowed them to make confident decisions in the context of current and required future profitability.

Example uses:

- Identify intra-network streaming opportunities by allowing least-cost/highest-productivity comparison across functions and transport modes.

- Supporting business cases for further investment in scanning and operating equipment by accurately showing the size of prize.

Clearly, there are a broad range of uses for a mature DPM, and senior management need to be aware of the universe of possibilities for putting the DPM to use so that they believe in the value of the project and provide it with their support.

However, they also need to be aware of two key learnings from failed DPM projects. DPM projects fail because they try to:

- model the whole business from day one, and/or

- build a model that supports every use case from day one.

There is a significant ramp up in the effort required to mature a DPM to an advanced level: more data, more complexity, more sophisticated uses that need to be supported. Therefore, companies can give their DPM projects a better chance of success by deciding up front:

- Which parts of the business would they like the DPM to cover,

- What uses do they want their DPM to be able to support, and

- In what order of priority do they need it?

In general, focus can be achieved using the 80:20 rule or by starting with the largest standardised service offering. For use cases, the value to the company may be self-evident, the senior leadership team may express a strong preference, or the options can be force ranked to achieve a priority listing. By agreeing these upfront and by defining their priority, the DPM will be focused on a clear set of targets that are highly valuable to the business.

Step 2: What is your current capability?

In this step the diagnostic develops a clear picture of the current capabilities of a company, and what these capabilities could deliver if a DPM were to be implemented.

Firstly, it is important to understand what makes a high-quality DPM.

As mentioned earlier, a DPM is a highly advanced cost allocation model, so it follows that the model is made up of allocations. At a basic level, allocations take the various costs of operating a business and spread them across the products and customers of that business.

The quality of the allocations drives the quality of the model. Allocation quality includes attributes like the accuracy, precision, granularity, scope, and timeliness of the data, and the strength of causality between an activity and the allocation of cost.

Consider this example; a freight company that provides a specialised, segregated help desk to its largest customers. The DPM might be said to have a high-quality allocation of customer service costs if it directly allocates the costs of this help desk to the large customers using this service. There is a clear causal link between the two.

In contrast, the model would have a low-quality allocation of customer service costs if the cost of this dedicated help desk was bundled up with the general customer service cost pool, and allocated equally to every customer. Although there is some connection between the customer activity and the cost, it is weak. Because it is weak, it limits the ability of someone using the model the generate insights and initiatives that can be relied upon.With this in mind, each component needs to be reviewed to identify the most significant capabilities that are currently present which could either support or limit the level of quality of a DPM.

The stages of allocation quality

Allocations can be ranked from Stage 1 to Stage 4, based on their Degree of Accuracy and the Degree of Effort to implement and maintain.

In general, a high-quality DPM would have Stage 3 or Stage 4 allocations for the major components of the cost of freight, and could attempt the same level for major overhead costs such as sales and customer service.

How do you determine what a ‘capability’ is?

Making this determination is not an exact science, and there is some art in deciding what constitutes a significant capability. Often, it is about documenting what is known about the operational processes by subject matter experts.

By way of example, at one company it became apparent from interviewing subject matter experts that some of their allocations would only be a Stage 1 allocation. This was because there was no detailed tracking of the method by which items entered the company’s network, so they couldn’t assign these costs directly to customers.

In making the assessment, consideration should be given to the level of quality that is supported by the:

Underlying cost pool. Granular allocations require granular financial data. If, for example, the financial data for Linehaul is consolidated so that the costs of different modes of transport are not separately visible, then this will limit the quality of the allocation to around Stage 2.

Activities or drivers. High-quality DPMs are directly connected to the company’s operational event data, such as the data streams from hand scanners used by delivery drivers. If this information is not available, it will be difficult to have high levels of confidence that the model reflects operating realities.

Once completed, senior management and key stakeholders will then have with a clear view of the level of quality of a DPM if the model were built based on the company’s current capabilities.

Step 3: What is your investment pipeline?

With a solid understanding of the company’s current capabilities, the next step is to understand the investment portfolio, both active and planned. This will help to identify which current gaps in capabilities will be improved in the near to medium-term, so that the DPM project can plan ahead to incorporate future changes.

The internal project management office should be able to provide a consolidated list of all active and planned projects. From this list, evaluate each project to determine the impacts. Some key questions are:

- What products will it impact?

- What types or segments of customers?

- What areas of the operation?

- Will it improve data availability?

- What will be the quality impact? For example, will it allow us to create Stage 3 Data-Driven allocations?

Once this assessment has been completed, the current capabilities can be compared with future capabilities. This will provide a clear picture of the prospective improvements in capability by identifying any major model components that can be firmly relied upon because they will achieve a Stage 3 or Stage 4 allocation quality, either now or in the near future.

This provides confidence to senior management that investing in a DPM process will continue to provide benefits. As new capabilities and information is developed, a high-quality DPM can easily tap into these new feeds of information to continue to improve the quality of the insights it provides.

Step 4: Where are the gaps?

Once the current state assessment and the investment pipeline have been documented, we can compare the two to see where the areas of opportunity are.

It will be obvious from the results of Step 3 as to which components are more advanced than others. This information can be used to design a DPM process that leverages the current capabilities, while also providing input into the forward investment plan to ensure that weaker areas of understanding will be addressed in future.

It is important to note that having a DPM which can only achieve Stage 1 or 2 allocations can still provide value to a company. We have observed many DPM projects that still deliver significant value, despite being seemingly handicapped by limited organisational data. This is because the rigorous design process and search for data-driven insights can highlight previously undiscovered areas of value, or help to dismantle long-held beliefs that have no basis in reality.

Step 5: What investments will close the gaps and what is the implementation plan?

With our current and near-term plans mapped out, the business will have a clear fact base from which to support a DPM process. They will understand current and planned future capabilities, and have identified the gaps in their capabilities. Having completed this process, the business may have identified capability gaps or opportunities to improve understanding across such areas as customer and product, network, systems and processes, and people. With these analyses completed, the project team and senior management can work to jointly agree a revised investment roadmap which supports a DPM implementation plan.

Finally, an improvement option for the PMO to consider is to start evaluating project proposals and business cases using a DPM lens. It could be made a part of project establishment that the project owner needs to document what contribution, if any, will be made to improving the ability of the organisation to understand itself. This information can be mapped against the major model components and be used as a project prioritisation measure. Projects which contribute significantly to improvements in information quality may be considered a higher priority than those that do not contribute, or detract from, the level of understanding.

Conclusion

Start right finish right

We have seen the power of successfully implemented DPMs, and how widely the positive impacts of the process spread across the business. We have also observed DPM processes done poorly, and know the costs of failure.

A structured diagnostic can help ensure that any future DPM project will be successful by identifying up-front the likely quality of the model and the areas where there are likely to be issues in developing a solid understanding of profitability. As an added benefit, it provides a clear view of capabilities, which can be used to direct investments where they will have greater impact in contributing to the understanding of the organisation.

How can PCG help you understand and improve your business?

The differences between beginners and expert competitors when it comes to DPMs are stark.

Experts are using DPMs to support initiatives across revenue management, operational productivity improvement, sales force effectiveness, and many other major profit and productivity improvement initiatives. They have the confidence to act because the DPM has become a trusted source of truth for all major functions in the business.

Having directed or supported hundreds of DPM engagements, including turning around those endeavours that have stalled, PCG have developed the expertise to confidently deliver DPM-based insights and initiatives for highly complex global and national freight and logistics companies. Contact us today to find out more about how we can add value to your business.

About Pacific Consulting Group’s Freight and Logistics practice

One of our core industry focuses, the Freight and Logistics practice has delivered profit and productivity improvement for leading companies around the world. We have worked in partnership with senior leaders across industry segments like parcel express, road/air/rail freight and intermodal providers, last-mile specialists, and 3PL. Our superior analytics, commercial focus, and industry experience have allowed us to deliver outstanding outcomes.